Save up to 50 % of energy

in commercial kitchen

See how our customer saves 130 MWh of energy and 17 tons of CO2 – per year

Read the Areim Ab Aallonharja (Espoo, Finland) case study or download the latest case studies.

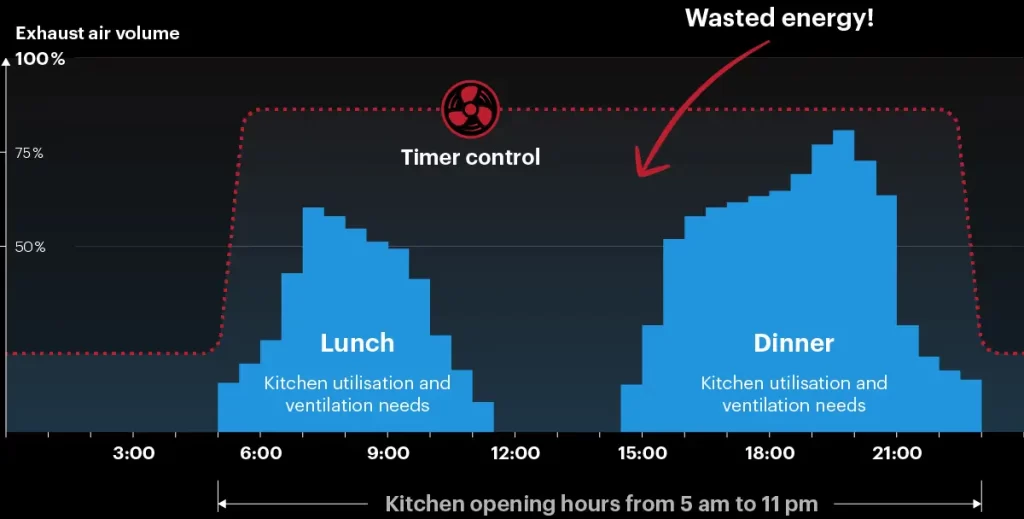

Why is the ventilation running at full power if no one is cooking?

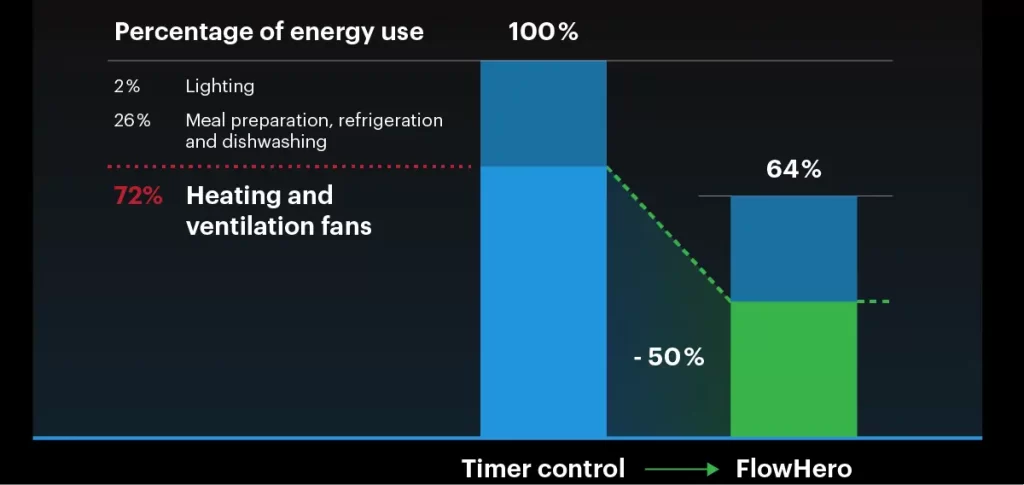

Professional kitchens consume 5–7x more energy than other commercial spaces. Most of the energy is used for ventilation and heating.*

If the kitchen utilisation rate varies, traditional timer-controlled ventilation blows out expensive treated air – up to thousands of litres per second!

* Motiva: Energy-efficient professional kitchen

Solution:

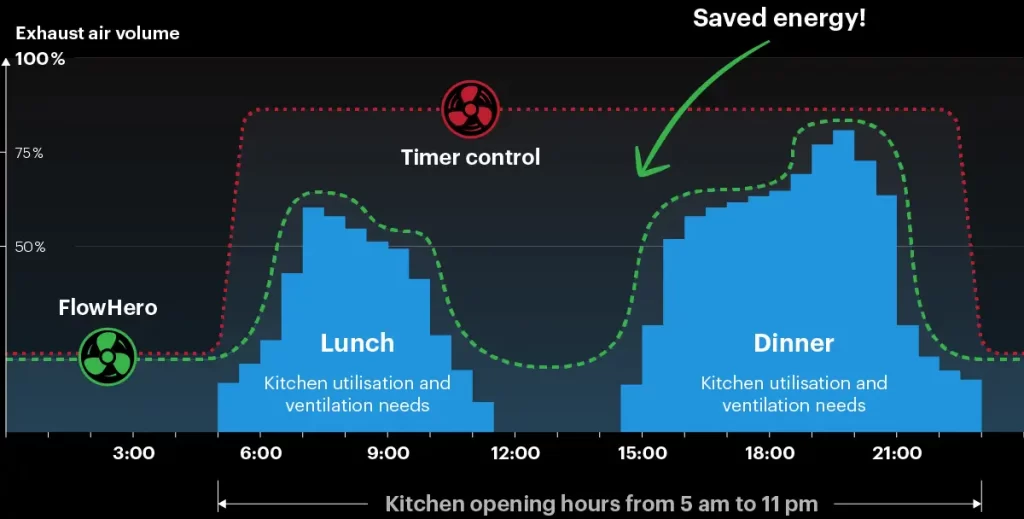

Demand Control Kitchen Ventilation – Safera FlowHeroThe new intelligent Demand Control Kitchen Ventilation system (DCKV), Safera FlowHero, ensures that ventilation operates at optimum efficiency at all times.

FlowHero controls the ventilation in real time according to the use of the kitchen, which reduces the energy consumption of the HVAC system by up to 50% without compromising indoor air quality.

Meet your sustainability goals and save money

FlowHero’s demand control ventilation saves energy and promotes sustainability and its reporting.

Reduce your carbon footprint and save money: up to 50% lower energy consumption for HVAC system.

Take care of your employees’ working conditions: active monitoring of air quality and lower kitchen noise levels.

Meet the requirements for sustainability certifications: verify energy savings and report progress automatically. Read more »

Safera is a member of Green Building Council Finland

Four easy steps to start saving energy

FlowHero is suitable for both new and existing professional kitchens, and it is available either as a system integrated into the hood or as a separately installed accessory. Here’s how to easily upgrade your existing commercial kitchen with FlowHero demand control kitchen ventilation.

Get a free energy savings estimate in one week

Make an informed investment decision

We install the system in 3 to 4 hours

Verify the benefits of FlowHero in 30 days

Get a free energy savings estimate in one week

Once we receive information about your property, we promise to deliver a free estimate within one week, including:

- Savings in heating and electricity (MWh)

- Savings in carbon footprint (tCO2)

- Savings in euros (€)

- Payback period of the investment

We only need the following information from your property:

- Kitchen supply and exhaust air volumes

- Timer control settings

- Power consumption of the exhaust and supply air fans (or we use estimates)

- Electricity and heating energy prices (or we use estimates)

- HVAC diagrams

We provide a free estimate with no obligations. Contact us, or download and fill out the estimate calculator yourself. A site visit can help refine the estimate, but it is not mandatory.

Make an informed investment decision

Based on the estimate, we provide a budgetary offer, enabling you to make an informed investment decision.

The offer includes:

- FlowHero system equipment and installation costs

- Estimated costs for necessary electrical work and automation design (performed by either our partner or a provider chosen by the customer)

- Estimates of payback period and annual savings in energy and carbon emissions

The investment is typically around €10,000 with a payback period of 2-4 years. See actual savings and paypack periods from our customers.

We install the system in 3 to 4 hours

The installation happens in two phases:

- The FlowHero system installation is completed without interrupting restaurant operations in 3-4 hours. FlowHero begins monitoring air quality and kitchen usage, storing the data in our cloud service.

- About 2-3 weeks after the installation, FlowHero is connected to the automation system. FlowHero starts controlling the ventilation based on demand, and the savings begin.

FlowHero is connected to the Variable Frequence Drivers or automation system with a wire (control signal 0-10 V), and it is compatible with all BAS systems. See examples of the functional description.

FlowHero is fully automatic, so it does not require any training for the restaurant staff.

Verify the benefits of FlowHero in 30 days

We provide a report on the performance of FlowHero and the realized savings 30 days after the control signal connection. We compare the data recorded by FlowHero before and after the connection, ensuring that savings are achieved without compromising air quality.

During the commissioning we monitor the system’s operational status remotely and can adjust settings as needed to ensure smooth implementation.

We also offer additional services for you:

- Maintenance contract with remote monitoring

- Sustainability reporting, including realized savings in energy and carbon emissions

- Analysis of kitchen utilization, air quality, and working conditions

Contact us and get a free estimation of energy savings!

How does FlowHero save energy?

More than two-thirds of a professional kitchen’s energy consumption is used for ventilation and heating. FlowHero can save up to 50% of this energy.

Energy savings depend on the utilisation rate of the kitchen, the ventilation equipment and the average temperature of the outside air, for example. Contact us and we will assess your potential for energy savings.

Savings start as soon as FlowHero is deployed.

The most significant savings are created in two ways:

1. Less heated or cooled supply air is needed

The heating energy of the supply air covers approximately 65% of the total energy consumption of professional kitchens. Blowing out the treated supply air unnecessarily wastes a tremendous amount of energy.

When less air is removed from the kitchen, there is also less need for expensively treated supply air.

2. Fans can be used at the lowest possible power

The powerful fans in professional kitchens are designed to move thousands of litres of air per second.

By controlling the exhaust and supply fans as needed, significant savings can be made on the energy consumed by the fans’ motors. In addition, the noise level in the kitchen will be reduced.

Download the latest case studies

Download the latest case studies and see how we help our customers to reach their sustainability goals.

Our customers save annually:

Campus restaurant, Espoo

Airflow Rate

Carbon Footprint

Energy Consumption

Energy Costs

Payback Time

Lunch Buffet, Espoo

Airflow Rate

Carbon Footprint

Energy Consumption

Energy Costs

Payback Time

Hotel Restaurant, Helsinki

Airflow Rate

Carbon Footprint

Energy Consumption

Energy Costs

Payback Time

Ghost Kitchen, Espoo

Airflow Rate

Carbon Footprint

Energy Consumption

Energy Costs

Payback Time

Contact us

We can evaluate the savings potential of your restaurant and present the actual results from our customer cases.

This is how FlowHero works

FlowHero is suitable for both new and existing professional kitchens, and it is available either as a system integrated into the hood or as a separately installed accessory.

This is how FlowHero works

FlowHero is suitable for both new and existing professional kitchens, and it is available either as a system integrated into the hood or as a separately installed accessory.

The FlowHero multi-sensor system monitors how the workstations are used and controls the ventilation as necessary.

At the same time, FlowHero monitors the indoor air quality in the kitchen to ensure good working conditions. FlowHero can control the ventilation individually or as a whole, and it is compatible with most ventilation systems.

FlowHero is available as a pre-integrated solution in Climecon’s ventilation systems or as a retrofit to existing professional kitchens.

Key features

Identifying different usage situations reliably

The FlowHero sensor unit is installed at the edge of the hood, where it monitors the use of the workstation in real time with several sensors, such as IR, temperature, humidity and presence sensors.

By combining sensor data, FlowHero can immediately determine what is being done at the workstation and how it affects the need for ventilation – even proactively.

Active monitoring of air quality

FlowHero monitors the air quality in the kitchen in real time so that energy is not saved at the expense of air quality. FlowHero is also able to determine if it is advisable to temporarily improve the ventilation before the air quality exceeds the limit values.

FlowHero monitors temperature, humidity, organic gases (TVOC), carbon dioxide (eCO2) and fine particulate matter (PM2.5).

Energy savings monitoring and reporting

FlowHero stores sensor and ventilation control data in Safera’s cloud service, where energy savings and air quality can be monitored almost in real time.

The cloud service makes it easy to verify and report on progress towards energy savings and responsibility goals.

Technical documentation

Here you can find technical documentation for you to download.

Green building certificates and FlowHero

If your goal is excellent results in the sustainability certifications, Safera FlowHero can bring additional points to the most common certifications, such as BREEAM, LEED and Green Key. With FlowHero, you can report energy savings and compare the change with previous energy consumption easily via the cloud service.

LEED

Energy and Atmosphere

Optimize Energy Performance

BREEAM

Ene 08 Energy efficient equipment

Solutions deemed to comply with the criteria for the reduction of equipment energy load from significantly contributing systems: Ref. F Commercial kitchen and catering facilities

Green Key

Restaurants, hotels and hostels

7. Energy

7.2 Heating, ventilation, and air- conditioning control systems must be in place.

Uniquely intelligent technology

with over 15 years of experience

Safera has been a pioneer in smart multi-sensor solutions for over 15 years. Our technology makes cooking safer and easier in over 300,000 homes around the world. Our sensor technology understands what’s going on in the kitchen. Now we also bring our know-how to professional kitchens by introducing a smart demand control ventilation system: Safera FlowHero.