Demand Control Kitchen Ventilation (DCKV) Case Study:

Castellum

Piispanhuippu

FlowHero demand control kitchen ventilation (DCKV) system clearly exceeded expectations at Piispanhuippu: kitchen air volume decreased by 67% (target 40%) and the payback period improved from 4,6 to 2,8 years.

Customer's savings per year:

Carbon Footprint

Energy Consumption

Energy Costs

Payback Time

Located in Espoo, Piispanhuippu is a modern office building completed in 2002 that provides high-quality spaces for multiple companies.

The property is known for its energy-efficient solutions and holds a BREEAM In-Use Excellent certification. The building is owned by Castellum and managed by Property Manager Marko Linna from Ceino.

Although the building was already well maintained and energy efficient, opportunities for additional energy savings were identified in the ventilation system. By upgrading the restaurant kitchen ventilation with the FlowHero demand-controlled ventilation system, the goal was to take the building’s energy efficiency one step further.

Having prior experience with FlowHero in other properties, Property Manager Linna proposed the solution to the owner.

Intelligent ventilation control instead of a static timer

Before the upgrade, the kitchen ventilation was operated by a conventional timer that started and stopped the fans at fixed times each day. FlowHero transformed the system into an intelligent, demand-based control: ventilation now adjusts automatically to the kitchen’s actual use instead of running on a predetermined schedule.

The installation was carried out in December 2024, with commissioning completed smoothly at the beginning of 2025. The devices were integrated into the building automation system, and real-time data collection began immediately after startup.

The first interim report confirmed that the savings became visible within just the first few months.

Expectations clearly exceeded – payback period only 2,8 years

The FlowHero system achieved results at Piispanhuippu that were significantly better than anticipated. The total air volume decreased by 67 %, compared to the original target of 40 %, directly reducing both energy consumption and operating costs.

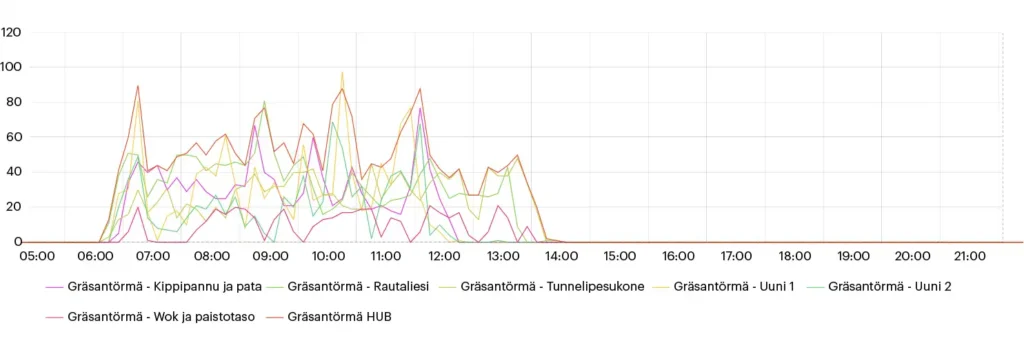

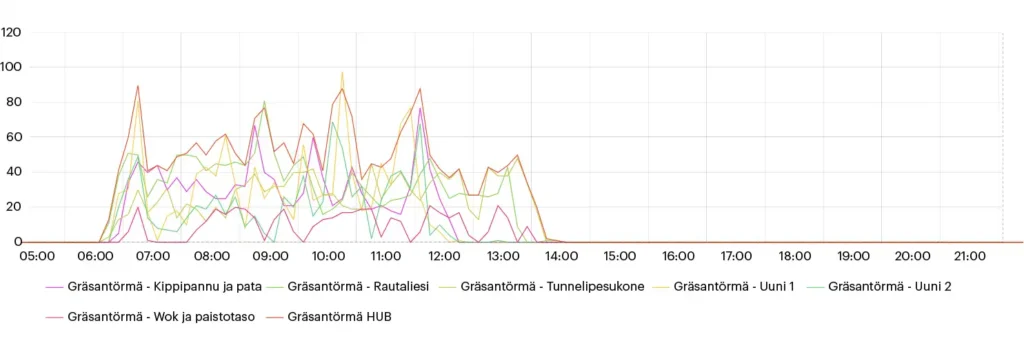

The results are based on measured reductions in ventilation air volume between November 2024 and October 2025, and on the corresponding calculated energy savings.

The total savings include both reduced fan electricity consumption and lower heating energy demand for supply air.

Reliable and easy to manage

FlowHero continuously measures air volumes and indoor conditions, with data monitored through Safera’s system.

Energy use can be compared directly to the previous timer-based operation, and verified savings can be documented through automatic reports.

FlowHero data revealed that the kitchen ventilation had often started too late compared to the actual start of kitchen activity. Demand control introduced flexibility — ventilation now responds to real use rather than fixed times, improving both energy efficiency and user comfort.

Summary and outlook

The FlowHero project at Piispanhuippu demonstrates that demand-controlled ventilation delivers measurable benefits even in office buildings where the baseline systems are already efficient.

The project was executed smoothly and exceeded its goals, offering a strong model for similar properties in the future.

See also:

FlowHero Case Study: Metos Personnel Restaurant

Metos, the Nordic leader in professional kitchen solutions, chose FlowHero DCKV for its own staff restaurant. The automated ventilation system delivers concrete energy savings and

RørosHetta x Safera: A collaboration that drives sales and earns recognition

Norwegian premium range hood brand RørosHetta reports on their website that adopting Sense technology (Safera’s Integral) has increased their sales by 32%.